Product Details

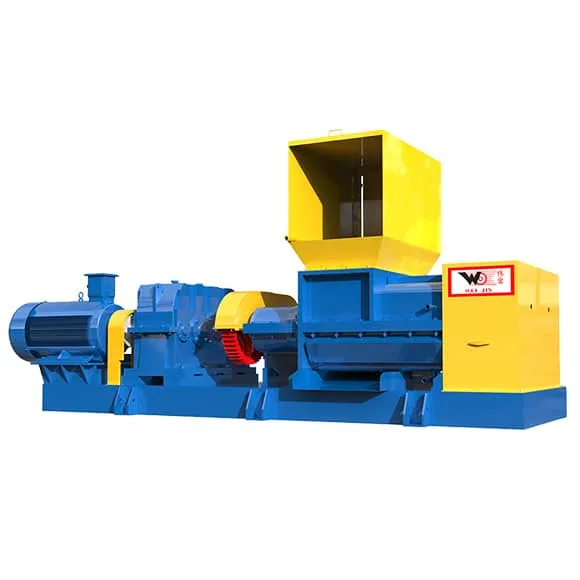

Dual Spiral Crusher

Integrates crushing, agglomerating, and semi-plasticizing in one machine. Replaces 3 traditional machines, achieving high capacity in small space.

- Cost & Space Saving: 1 machine replaces 3, purchase cost reduced by 60%

- Durable & Low Consumption: High wear-resistant alloy, no frequent blade changes

- Adjustable Fineness: 0.5-50mm freely adjustable, no secondary processing needed

- Eco-friendly & Safe: Low noise (≤85dB), low dust, environmentally compliant

- Anti-entanglement: Reverse emergency device, solves jamming for textiles/rubber

- All-Industry Adaptability: Textiles, plastics, rubber, medical waste

Product Overview

The Dual Spiral Crusher is an innovative equipment designed by DAKY with 20 years of manufacturing experience to solve core problems in solid waste treatment. Addressing pain points such as insufficient capacity of single machines, limited workshop space, and cumbersome process connections, this equipment innovatively integrates crushing, agglomerating, and semi-plasticizing functions. It not only replaces the traditional "crusher + agglomerator + plasticizer" setup but also achieves high efficiency with only 1/3 of the footprint, significantly reducing procurement and operating costs. Its low-speed spiral structure and anti-entanglement design are particularly suitable for processing flexible and tough materials like textiles, plastics, and rubber, helping you achieve green and efficient solid waste resource utilization.

Core Technical Advantages

Solves 5 major production pain points with 1 machine, reducing costs by 50%.

- Cost & Space Saving, 1 Machine Replaces 3: Innovative integrated design replaces traditional independent lines. Purchase cost reduced by 60%, footprint is only 1/3 of traditional lines, enabling efficient layout even in small workshops.

- Durable & Low Consumption, 24h Continuous Operation: Core blade set made of high wear-resistant alloy, durable, eliminating frequent blade changes or sharpening. Supports 24h continuous operation, significantly improving efficiency and reducing maintenance costs.

- Flexible Output Fineness, One-Step Process: Supports 0.5-50mm output specification adjustment. Stable control for crushing, agglomerating, or semi-plasticizing effects. Finished product directly adapts to downstream injection molding or pelletizing equipment, simplifying the process.

- Eco-friendly & Safe, Green Production: Low-speed spiral design keeps noise within 85dB, with extremely low dust emissions, protecting operator health and facilitating environmental compliance.

- Anti-entanglement, Handles Complex Materials: Designed for flexible and tough materials like textiles and rubber, equipped with intelligent reverse emergency device. Effectively prevents entanglement during continuous feeding, ensuring smooth production.

Applicable Materials & Areas

Applicable Materials

- Textiles: Old clothes, cotton cloth, polyester cloth, denim, non-woven fabric, oxford cloth, woven bags, ton bags, yarn scraps.

- Plastics: PP, PE, PET, LDPE, HDPE plastics, agricultural film, battery film, foam, mineral water bottles, plastic baskets, injection molding scraps.

- Rubber Products: EVA, natural rubber, synthetic rubber, tire rubber, silicone, cord fabric rubber, sponge, rubber seals.

- Special Materials: Compliant medical waste, industrial waste residue, leather waste (pig/cow/sheep skin).

Application Areas

- Resource Recycling: Efficiently process various recycled wastes, improving resource utilization.

- Textile/Garment Processing: Process scraps and old fabrics for closed-loop utilization.

- Plastic/Rubber Pelletizing: Provide high-quality pre-treated material to optimize pelletizing quality.

- Medical Waste Treatment: Compliant and safe treatment of special medical waste.

| Technical Parameters | SPJ-300 | SPJ-450 | SPJ-550 | SPJ-650 |

|---|---|---|---|---|

| Main Shaft Speed | 47r/min | 47r/min | 47r/min | 47r/min |

| Power | 55/75kw | 90/110kw | 132/160kw | 200/250kw |

| Moving Knife Diameter | 300mm | 450mm | 550mm | 650mm |

| Capacity | 200-400kg/h | 400-800kg/h | 800-1500kg/h | 1500-2500kg/h |

Configuration Notes

1. About Us: A Solid and Reliable Professional Partner

1.1 Company Profile

Zhanjiang Daqi Technology Co., Ltd. is rooted in Zhanjiang, Guangdong, focusing on the R&D and manufacturing of crushing/grinding equipment, providing resource utilization solutions for industrial waste such as carbon fiber and glass fiber. With over 20 years of industry experience, we help customers convert waste materials into high-value resources, achieving a win-win situation for environmental protection and economic benefits.

1.2 History

- 2004-2015: Technical Accumulation Phase

The founding team focused on industrial material processing challenges, accumulating core capabilities in mechanical design and wear-resistant materials through extensive practice, laying the foundation for stable and durable equipment. - 2016-2020: Breakthrough & Innovation Phase

Following the lightweight trend in manufacturing, we formed a special R&D team to overcome high-efficiency processing technologies for composite materials like carbon fiber and glass fiber, developing low-temperature grinding paths. - 2021-Present: Industry Leading Phase

Successfully launched the carbon fiber grinding series equipment, forming a technical barrier. Products cover over 100 countries globally, becoming a trusted partner for new material enterprises.

1.3 Expert Team

[Boss Name] - Founder/Chairman

Grew from a frontline mechanic to a technical leader, with 30 years of mechanical R&D experience. Led the low-temperature low-damage grinding technology, solving processing problems for carbon fiber and glass fiber, holding over 20 invention patents.

[Uncle Fei Name] - On-site Technical Director

Responsible for global project installation, commissioning, and process optimization, precisely adjusting equipment according to customer production environments to ensure stable and efficient operation.

[Name] - Chief Technical Consultant

Leads full-process product R&D, strictly controlling technical standards from design to engineering verification, promoting automation and intelligent upgrades.

[Manager Lai] - Senior Solution Manager

Deeply analyzes customer needs, translating technical parameters into customized equipment solutions, providing complete engineering support.

[Zhaolian] - Solution Manager

Focuses on pre-sales technical communication and solution configuration, efficiently connecting with customer needs to ensure a smooth service experience throughout.

2. Core Capabilities: Focusing on Industrial Waste Solutions

2.1 Technical Advantages

- High Efficiency & Low Consumption Lower unit energy consumption, daily processing capacity up to 20 tons (depending on material).

- Low Damage Grinding Original 'material grinding material' technology (e.g., 'carbon grinding carbon'), no tool contact, protecting fiber aspect ratio and original characteristics.

- Precise Temperature Control Liquid cooling system controls grinding temperature to prevent damage to heat-sensitive materials.

- Adjustable Particle Size From 1cm chopped fibers to 400-mesh fine powder, with uniform particle size distribution.

- Continuous Operation 24-hour uninterrupted production, ensuring stable capacity.

- Eco-friendly Design Fully enclosed grinding chamber suppresses dust, complying with industrial environmental requirements.

2.2 Product System

We provide a modular, customizable product system from core single machines to complete production lines:

Single Machine Equipment

Ready-to-use, quick production launch.

Complete Line Solutions

One-stop service from design to commissioning.

Customized Solutions

Tailored for special raw materials and processes.

Core Products:

Carbon Fiber Grinder

Low-temperature grinding technology for processing offcuts, retaining fiber performance, producing powder below 400 mesh for high-value fields like conductive coatings.

Glass Fiber Grinder

Optimized for glass fiber characteristics, converting crushed material into raw materials for building materials and plastic modification, solving waste disposal and resource utilization problems.

Composite Material Grinder

Processes high-hardness materials like wind turbine blades and fiberglass waste, achieving resource utilization.

Spiral Crusher

Bladeless design, processing soft waste like fabrics, films, and rubber, achieving crushing, agglomeration, and semi-plasticization integration.

2.3 R&D & Manufacturing Strength

Core team members possess over 15 years of industry experience, ensuring mature and reliable technical solutions. From R&D to production, every link is led by senior experts to avoid technical gaps.

2.4 Quality Assurance System

Experience-Driven Manufacturing

Production team backbone averages 15 years of experience, precisely executing process standards.

Full-Link Traceability

Unique ID for every part, linking material batches and suppliers to ensure source quality control.

Precision Craftsmanship

CNC machining, laser welding, and other processes guarantee equipment precision and durability.

Lifetime Service Archive

Establishing 10+ year technical archives for each machine to support long-term maintenance and upgrades.

制造品质与服务支持

5.1 精益制造:耐用的保障

全流程可追溯

核心组件建立唯一身份编号,可追溯至原始材料批次,从源头确保品质稳定。

精密加工工艺

关键部件采用CNC加工中心制造,结合激光焊接工艺,确保设备结构的高精度与长期耐用性。

资深团队打造

核心生产环节由拥有15年以上经验的技师带队,严格执行工程标准。

5.2 全生命周期服务

Need Technical Support?

我们的工程师团队随时准备为您解答关于安装、调试、维护的任何问题。

Contact Support