Product Details

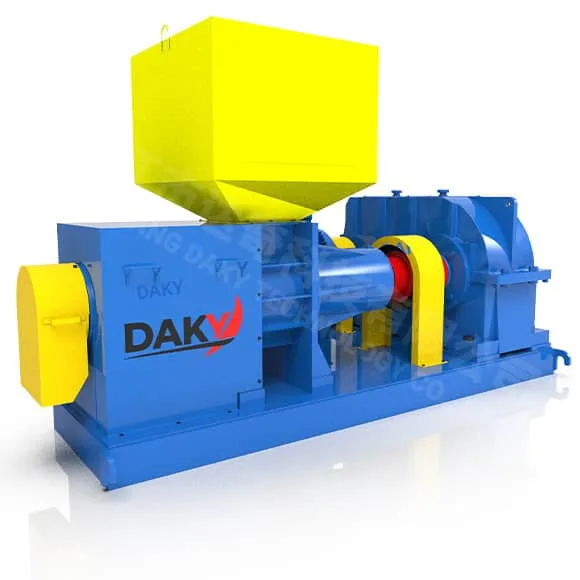

Glass Fiber Grinding Machine

Professional processing of glass fiber waste, converting it into uniform fine powder under 400 mesh through fine grinding for efficient recycling.

- Anti-entanglement: Special design prevents clogging during operation

- All-form Adaptation: Suitable for raw silk, hard silk, mesh, and other glass fiber forms

- Adjustable Fineness: 50-400 mesh adjustable, with screening and dust collection

- Dust-free: Professional dust collection system ensures no emissions

- Durable: Cast body + high-hardness alloy parts resist fiber wear

- Cost Saving: Replaces third-party disposal, turning hazardous waste into value

Product Introduction

Our Glass Fiber Grinding Machine is an efficient, stable, and durable solid waste processing equipment. It uses low-temperature grinding technology and liquid cooling to ensure glass fiber properties are not degraded by heat. Optimized for glass fiber wear characteristics, it stably processes various fiberglass cloth, chopped strands, and rock wool scraps, converting them into adjustable fine powder. This solves waste disposal problems and turns waste into valuable resources for building materials and plastic modification, achieving cost reduction and environmental protection.

Core Technical Advantages

Designed for glass fiber grinding, solving entanglement, wear, and dust problems.

- Low-temp Physical Grinding: Uses low-speed pressure-free grinding with liquid cooling to avoid heat-induced property changes. Maximizes aspect ratio preservation for high-quality recycled powder.

- Durable for Harsh Conditions: Key components feature reinforced wear-resistant materials and optimized structures for high-wear materials, ensuring long-term stable operation.

- Adjustable Fineness: Output fineness is freely adjustable under 400 mesh, meeting requirements for high-end composites or general fillers, with customization available.

- Eco-friendly Production: Innovative screen-free design solves fiber entanglement at the source. Low-speed operation ensures low noise and dust, complying with modern environmental standards.

- Circular Value: Supports continuous feeding and production, efficiently converting industrial waste into reusable resources, helping enterprises reduce costs and increase efficiency.

Applicable Materials & Areas

Applicable Materials

- Glass Fiber Scraps

- Chopped Strands

- Cutting Scraps

- Textile Waste

- Fiberglass Cloth

- Fuzz

- Rock Wool

- Fireproof Felt

Application Areas

- Building Materials: As fillers for putty powder, thermal mortar, concrete reinforcers.

- Plastic Modification: Reinforcing plastics (PP, PA) for strength, heat resistance, and stability.

- Friction Materials: As asbestos substitute for brake pads and clutches.

- FRP Recycling: Recycling FRP waste into regenerative composite materials.

| Model | ZFS-250 | ZFS-450 | ZFS-600 |

|---|---|---|---|

| Voltage/Freq | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Power (kw) | 15 | 75/90 | 110 |

| Capacity | 20 - 40kg/h | 300 - 500kg/h | 600 - 1000kg/h |

| Dimensions (mm) | 2000x820x1680 | 2920X1730X1900 | 3491X1980X2094 |

| Weight | 1T | 5T | 8T |

Configuration Notes

- Voltage: 3-phase 380V/400V/415V/440V, 50Hz/60Hz (Customizable per region)

- Core Power: Top domestic brands (e.g., Guomao Reducer, Xindali Motor), or specified brands.

- Safety: Soft start standard; optional Reversal Device for anti-load start protection.

- Control: Fixed frequency or variable frequency motors available based on processing needs.

1. About Us: A Solid and Reliable Professional Partner

1.1 Company Profile

Zhanjiang Daqi Technology Co., Ltd. is rooted in Zhanjiang, Guangdong, focusing on the R&D and manufacturing of crushing/grinding equipment, providing resource utilization solutions for industrial waste such as carbon fiber and glass fiber. With over 20 years of industry experience, we help customers convert waste materials into high-value resources, achieving a win-win situation for environmental protection and economic benefits.

1.2 History

- 2004-2015: Technical Accumulation Phase

The founding team focused on industrial material processing challenges, accumulating core capabilities in mechanical design and wear-resistant materials through extensive practice, laying the foundation for stable and durable equipment. - 2016-2020: Breakthrough & Innovation Phase

Following the lightweight trend in manufacturing, we formed a special R&D team to overcome high-efficiency processing technologies for composite materials like carbon fiber and glass fiber, developing low-temperature grinding paths. - 2021-Present: Industry Leading Phase

Successfully launched the carbon fiber grinding series equipment, forming a technical barrier. Products cover over 100 countries globally, becoming a trusted partner for new material enterprises.

1.3 Expert Team

[Boss Name] - Founder/Chairman

Grew from a frontline mechanic to a technical leader, with 30 years of mechanical R&D experience. Led the low-temperature low-damage grinding technology, solving processing problems for carbon fiber and glass fiber, holding over 20 invention patents.

[Uncle Fei Name] - On-site Technical Director

Responsible for global project installation, commissioning, and process optimization, precisely adjusting equipment according to customer production environments to ensure stable and efficient operation.

[Name] - Chief Technical Consultant

Leads full-process product R&D, strictly controlling technical standards from design to engineering verification, promoting automation and intelligent upgrades.

[Manager Lai] - Senior Solution Manager

Deeply analyzes customer needs, translating technical parameters into customized equipment solutions, providing complete engineering support.

[Zhaolian] - Solution Manager

Focuses on pre-sales technical communication and solution configuration, efficiently connecting with customer needs to ensure a smooth service experience throughout.

2. Core Capabilities: Focusing on Industrial Waste Solutions

2.1 Technical Advantages

- High Efficiency & Low Consumption Lower unit energy consumption, daily processing capacity up to 20 tons (depending on material).

- Low Damage Grinding Original 'material grinding material' technology (e.g., 'carbon grinding carbon'), no tool contact, protecting fiber aspect ratio and original characteristics.

- Precise Temperature Control Liquid cooling system controls grinding temperature to prevent damage to heat-sensitive materials.

- Adjustable Particle Size From 1cm chopped fibers to 400-mesh fine powder, with uniform particle size distribution.

- Continuous Operation 24-hour uninterrupted production, ensuring stable capacity.

- Eco-friendly Design Fully enclosed grinding chamber suppresses dust, complying with industrial environmental requirements.

2.2 Product System

We provide a modular, customizable product system from core single machines to complete production lines:

Single Machine Equipment

Ready-to-use, quick production launch.

Complete Line Solutions

One-stop service from design to commissioning.

Customized Solutions

Tailored for special raw materials and processes.

Core Products:

Carbon Fiber Grinder

Low-temperature grinding technology for processing offcuts, retaining fiber performance, producing powder below 400 mesh for high-value fields like conductive coatings.

Glass Fiber Grinder

Optimized for glass fiber characteristics, converting crushed material into raw materials for building materials and plastic modification, solving waste disposal and resource utilization problems.

Composite Material Grinder

Processes high-hardness materials like wind turbine blades and fiberglass waste, achieving resource utilization.

Spiral Crusher

Bladeless design, processing soft waste like fabrics, films, and rubber, achieving crushing, agglomeration, and semi-plasticization integration.

2.3 R&D & Manufacturing Strength

Core team members possess over 15 years of industry experience, ensuring mature and reliable technical solutions. From R&D to production, every link is led by senior experts to avoid technical gaps.

2.4 Quality Assurance System

Experience-Driven Manufacturing

Production team backbone averages 15 years of experience, precisely executing process standards.

Full-Link Traceability

Unique ID for every part, linking material batches and suppliers to ensure source quality control.

Precision Craftsmanship

CNC machining, laser welding, and other processes guarantee equipment precision and durability.

Lifetime Service Archive

Establishing 10+ year technical archives for each machine to support long-term maintenance and upgrades.

制造品质与服务支持

5.1 精益制造:耐用的保障

全流程可追溯

核心组件建立唯一身份编号,可追溯至原始材料批次,从源头确保品质稳定。

精密加工工艺

关键部件采用CNC加工中心制造,结合激光焊接工艺,确保设备结构的高精度与长期耐用性。

资深团队打造

核心生产环节由拥有15年以上经验的技师带队,严格执行工程标准。

5.2 全生命周期服务

Need Technical Support?

我们的工程师团队随时准备为您解答关于安装、调试、维护的任何问题。

Contact Support