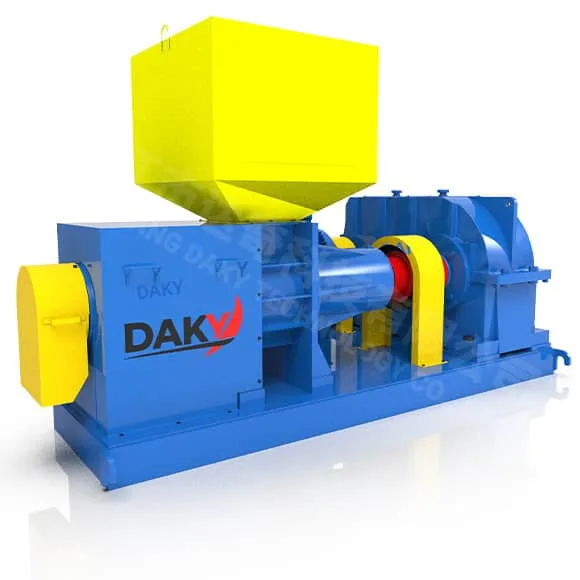

Built for Efficiency & Durability

High Efficiency & Energy Saving

Optimized power system for lower specific energy consumption. Daily capacity up to 15-20 tons (depending on model and material properties), meeting diverse production needs.

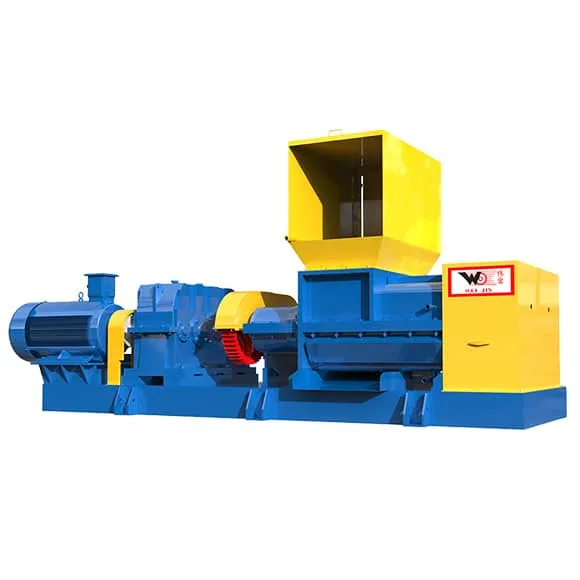

Low-Damage Grinding

Proprietary "Material-on-Material" technology (e.g., "Carbon-on-Carbon") with low-speed grinding (non-high-speed shearing) effectively protects fiber aspect ratio and strength, reducing loss rates.

Blade-Free Design / Easy Maintenance

No tangling or clogging, suitable for continuous production. Easy to clean and maintain, reducing downtime and improving overall productivity.

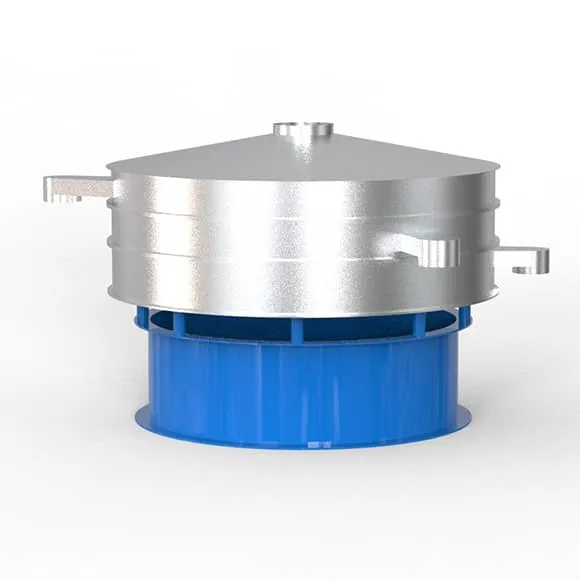

Adjustable Fineness

Supports flexible adjustment from 3mm chopped fibers to 20–400 mesh fine powder, with uniform particle size distribution to adapt to different process requirements.

Low Noise & Eco-Friendly

Enclosed design ensures a dust-free workshop and meets environmental protection requirements.

21+

Countries Served Globally

20+ Years of Engineering Excellence

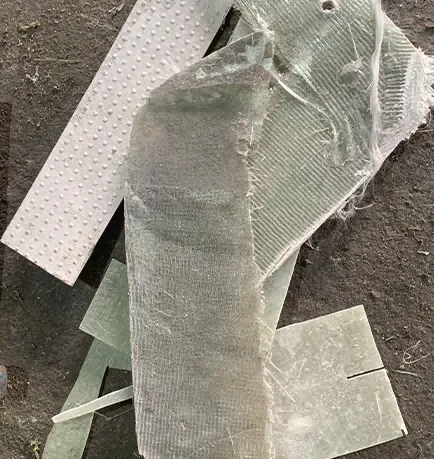

Zhanjiang Daqi Technology Co., Ltd. is a professional manufacturer of crushing/grinding equipment, dedicated to providing comprehensive solid waste treatment solutions. Through customized high-efficiency equipment and services, especially in high-tech composite materials such as carbon fiber, basalt fiber, glass fiber, and FRP, we ensure meeting customers' unique production needs, solving pain points in waste disposal, improving efficiency, and promoting manufacturing towards a greener and more sustainable direction.

2004-2015: Founding & Foundation, established "Precision Grinding" as core. 2016-2020: Exploration & Breakthrough, conquered processing difficulties of brittle materials like carbon fiber. 2021-Present: Maturity & Leadership, launched industry-leading carbon fiber grinding equipment, building technical barriers.

21+

Years of Experience

100+

Countries Exported

3k+

Customer Cases

10k/㎡

Production Base (sqm)

21 Years of Heritage

Core staff with 15+ years experience, ensuring quality from procurement to delivery.

Full Process Traceability

One-code-per-item management, tracing core components to batches with premium supply chain control.

24h Rapid Response

Global service network with engineers on standby to ensure continuous efficient operation.

Customized Solutions

Providing full customized services from process design to equipment selection based on client needs.

Want to know more?

Call us now!!

Mon - Sat : 10am - 07pm

Empowering Diverse Industries

Start Your Custom Project

Backed by Experts, Trusted by Users

30+ Years of engineering experience

Supporting you end-to-end.

With 20+ years of integrated R&D, production and after-sales experience, our core technologies are mature. Strict standards apply from component selection to assembly, and quality is verified by customers in 100+ countries globally.

Yes. Mail or deliver your fiber waste samples – we’ll adjust the equipment for satisfactory results, and sign the contract only after confirmation to protect your interests.

Absolutely. The production waste of composite material manufacturers can be reused in production after processing, realizing a closed loop of "production - waste - recycling - production", which not only reduces costs but also reduces waste.

Yes. We will conduct on-site inspections or design special discharge connection devices based on the production line parameters you provide to realize seamless connection between the grinding equipment and the existing production line, improving production efficiency.

CE certification serves as market access documentation for Europe. Holding this certification ensures the equipment complies with EU safety standards, and we already have clients from Italy, the Czech Republic, and the Netherlands in Europe using our equipment.